A coalescing test bench is a specialized apparatus used to evaluate the performance of coalescent cartridges and oil mist eliminators in removing oil-air aerosols. These devices are commonly employed in industrial settings to maintain air quality by capturing oil mist and aerosols, particularly in applications like Lube Oil Console for Gas turbines, metalworking, and compressed air systems.

Here's an overview of how a coalescing test bench works and its role in assessing the efficiency of coalescent cartridges and oil mist eliminators:

In summary, a Coalescing Test Bench is a critical tool for evaluating the efficiency of coalescent cartridges and oil mist eliminators in capturing oil-air aerosols. This assessment is crucial for maintaining air quality and preventing oil contamination in industrial processes, ensuring that these devices perform effectively and meet specific efficiency standards.

The Coalescing Test Bench is designed to evaluate air-oil mist filtration performances of the filtration elements and vessel during time. The test bench has been designed to allow the testing of two different arrangement for the filter:

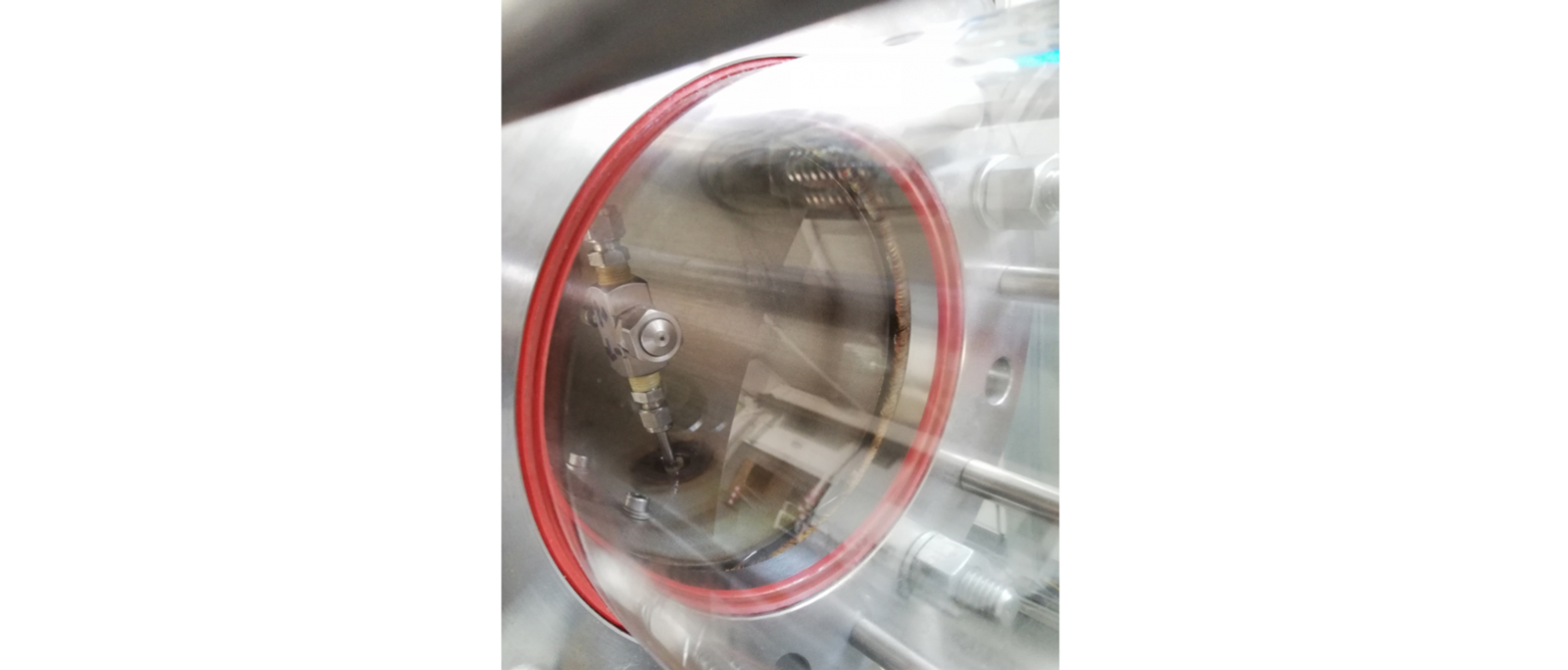

To reproduce the real working conditions of the tested filters, the test bench has been designed to generate an oil mist aerosol that is dispersed into the air stream using an atomizer nozzle driven by hot compressed air.

The Coalescing Test Bench has all the necessary equipment and instrumentations to allow the reliability and repeatability of the test. The test bench allows the remote control of the tests using the Control System that performs all the automatic controls, the main control loops are:

The control System also performs the safety control loops in case of any malfunction, stopping the test and bringing the test bench in a safe state.

The Coalescing Test Bench has air sampling points allowing the characterization of air-oil mist and the determination of number and mass separation efficiency.

Evaluable variables are:

Brochure Coalescing Test Bench

(PDF - 838.26 KB)